Transforming materials into sustainable packaging solutions

Through materials innovation, we work with customers to turn complex challenges into durable, sustainable packaging solutions that perform in the real world.

Why materials innovation matters

Materials shape the future of sustainable packaging.

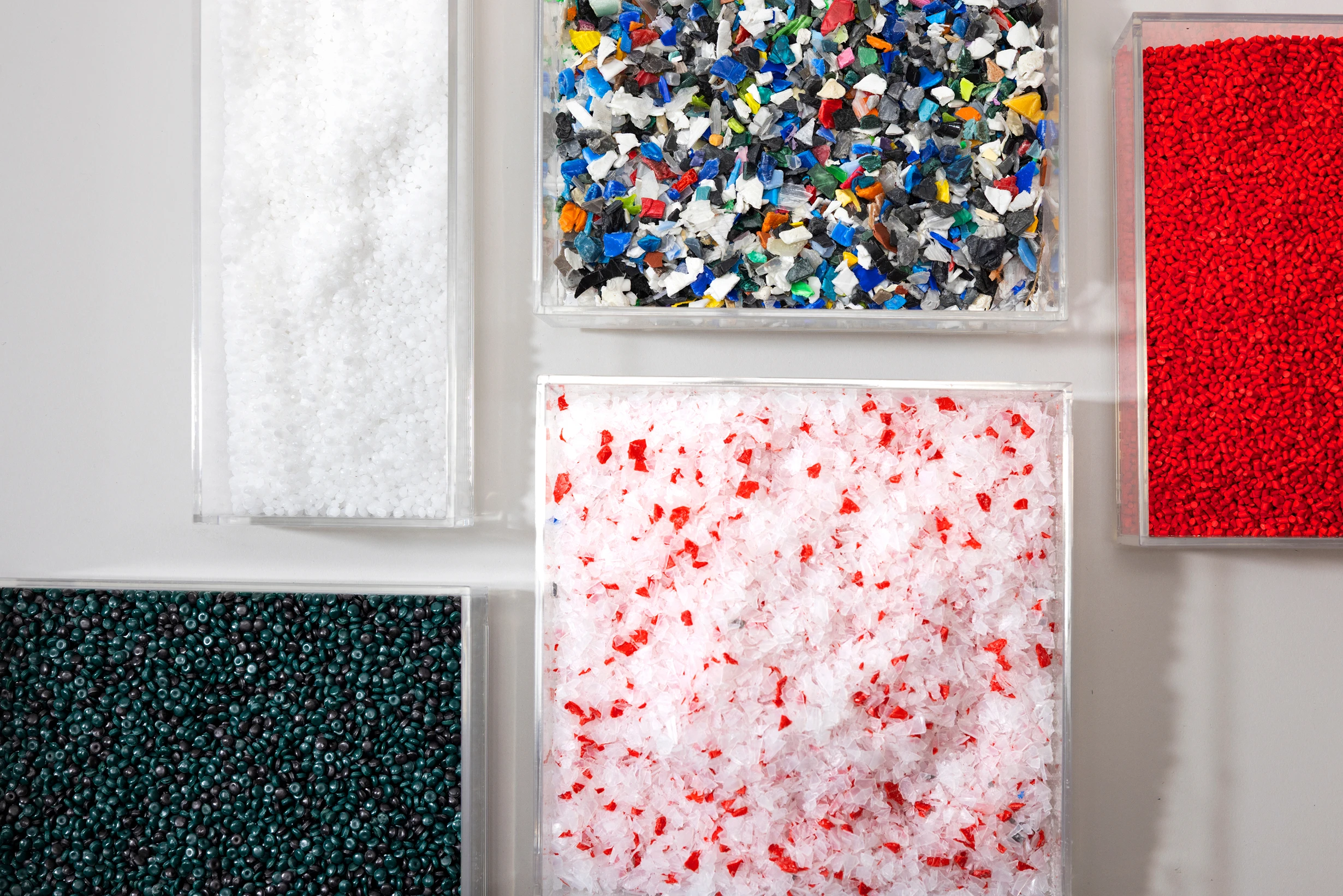

At IPL Schoeller, we drive innovation that balances performance and sustainability. By using recycled plastics, designing for recyclability, and extending product life, we keep resources in use for longer.

Beyond recyclability, we explore new materials to redefine what sustainable packaging can be, turning hard-to-recycle waste into durable products that support a circular economy.

Smart materials for real-world performance

Rethinking materials & performance

Case study

Iconic Red Up to 97% of recycled material

Coca-Cola Europacific Partners’ iconic red crates, ideated by the IPL Schoeller Innovation team, are made from 97% recycled materials, 85% reused crates and 15% discarded tulip nets.

Case study

Once a beverage carton, now a long-lasting crate

IPL Schoeller and Tetra Pak have created durable transport crates from recycled beverage cartons, cutting waste and supporting a circular economy.

Case study

Giving value to maritime plastic waste

In partnership with AB InBev, we’ve developed a Corona Extra beer crate crafted from over 91% recycled materials, including discarded fishing nets and ropes.

Buy Back Program

Circularity in action: the IPL Macro Buy Back Program

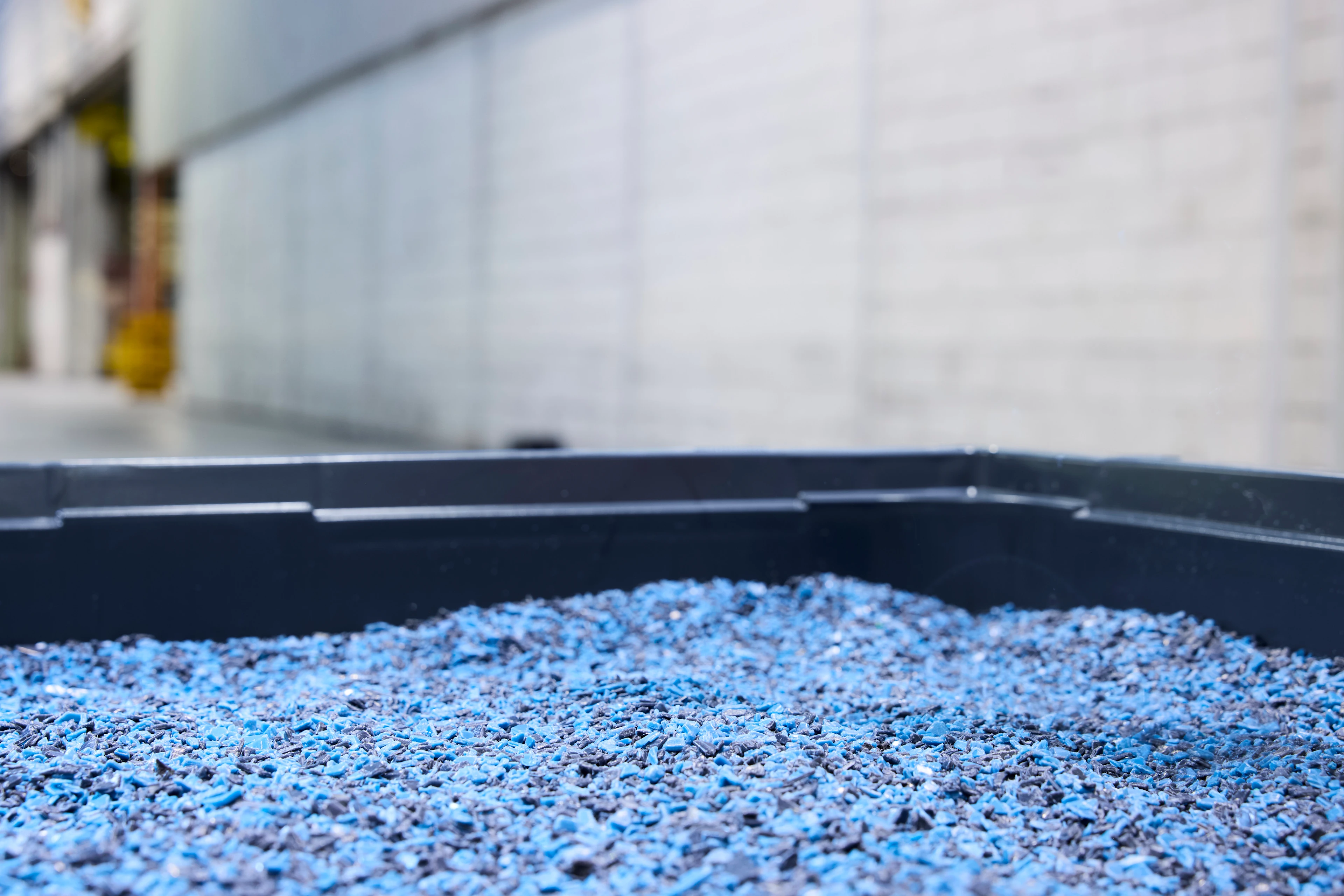

As part of IPL Schoeller, IPL Macro leads by example in closing the loop on plastics across North America. Through its Buy Back Program, used products are collected, reground, and cleaned to remove impurities, then reprocessed into uniform pellets for reuse in new applications. This circular approach reduces transport emissions, keeps materials in use, and increases the recycled content in future products.

Get in touch

Contact us today to explore how our solutions can work for your business

We help you navigate the complexities of your industry as your trusted partner.

FAQ

Our experts collaborate with you to turn complex waste streams into new possibilities. Get in touch to explore recycled and upcycled material solutions tailored to your goals.

We select materials that reduce waste, extend lifespan, and support circularity while maintaining strength and reliability.

By using recycled and upcycled inputs, reducing virgin plastic, and designing lightweight, durable packaging. These choices lower transport emissions, extend product life, and reduce overall carbon footprints.

Yes. We upcycle waste streams such as fishing nets, tulip nets, and more into durable transport crates.

Our unique approach includes a dedicated Material Innovation Lab in Hardenberg, where a specialized team of 5 experts works with innovative materials to enhance product performance. With a test centre on-site, we ensure that every solution meets the highest industry standards and customer needs.